Dibutyl Maleate DBM

CAS 105-76-0

DESCRIPTION

Dibutyl Maleate (DBM) it’s a derivative of butyl maleate. It’s an unsaturated ester which is a clear, colorless liquid with a characteristic “ester” odor.

It is miscible with methanol, ethanol, acetone, diethyl ether, N,N-dimethyl formamide and toluene,

It is not miscible with aliphatic hydrocarbons and is slightly miscible with water.

Under the action of heat and in the presence of acids or bases, DBM transposes into fumaric acid dialkyl ester.

DBM contains about 1-5% fumaric acid dialkyl ester and 1-2% alkoxysuccinic acid dialkyl ester.

USE

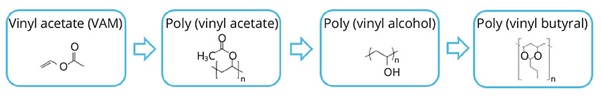

DBM is widely used as a liquid plasticizer for vinyl and acrylic emulsion polymerization, and is used for copolymers applications involving PVC, plastisols and vinyl acetates for paints, adhesives, and synthetic lubricants.

DBM is used in various resins and in the preparation of emulsions for the paper industry, textile and lubricant additives.

DBM is also a suitable intermediate for use in organic synthesis, in the production of derivatives of succinic acid.

Dibutyl Maleate is used for creating sulfosuccinate surfactants in detergents and paints.

DBM offers excellent rheological properties, and it can improve adhesion, flexibility and waterproofing in inks and paints. It also improves the UV filtration power.

Hydrophobicity and water resistance of the PVAc latex films were increased by using DBM as comonomer.

It is used in synthesis resin and dope material, and is used in petroleum industry, fabric, plastic, and paper industrial dipping agent, dispersive agent, adhesive, accelerant, pesticide, surface active agent and others.